Find your product now in our new webshop!

You can now access detailed product information and data sheets in our new eStore.

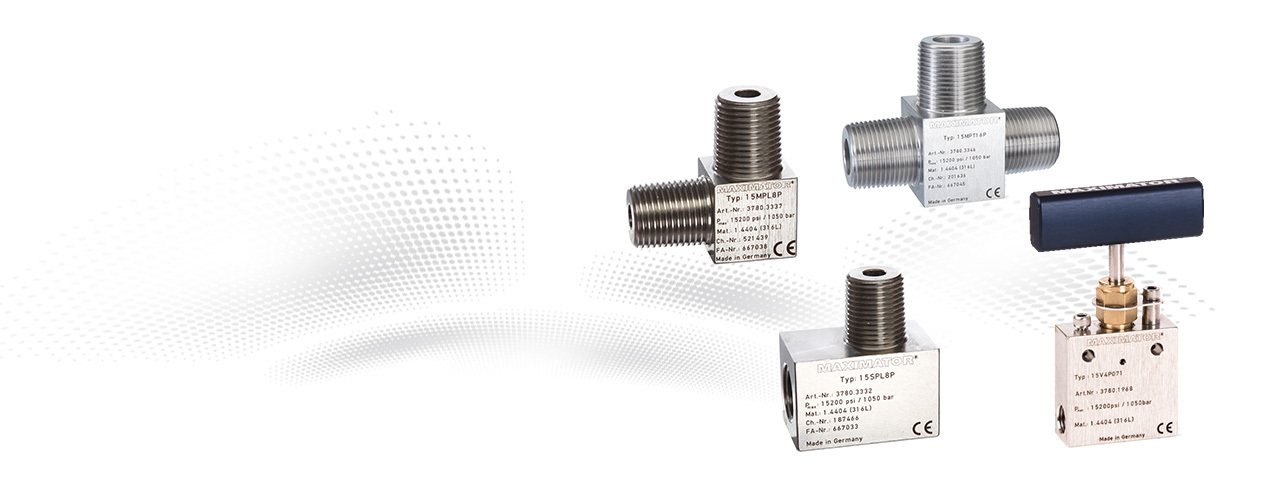

Pipe Valves, Fittings and Nipple features

- Rising stem design

- 316 L (1.4404) wetted parts for excellent corrosion resistance

- Metal-to-metal seating achieves bubble-tight shut-off, longer stem and seat life, greater durability for repeated open and close cycles

- PTFE and carbon packing with metal back-up rings offers reliable stem to body sealing.

- Non-rotating stem prevents stem to seat galling

- Stem sleeve and packing gland materials have been selected to achieve optimum thread cycle life and reduced handle torque. All stem sleeve threads are rolled, assuring smooth operation

- Two different valve body patterns, with choice of vee or regulating type stem tip

Pipe Valves

MAXIMATOR Pipe Valves of the 15V series have a cold-machined stainless steel body. Valve bodies are available in two different designs and can be equipped with regulating stem.

A special feature is the non-rotating stem which ensures a long life and high reliability. MAXIMATOR high pressure valves feature a metal sealing with a high level of safety and reliability under adverse operating conditions.

Pipe valves may be used with both gases and all fluids. Their traceability is ensured through extensively documented data (batch number, max. pressure, material number, type designation).

Pipe Fittings

MAXIMATOR Pipe Fittings are designed for liquid and gas applications. The P Series Fittings are available from 1/4” to 1”NPT to 15,000 psi.

Available in eleven different designs including Elbows, Tees, Crosses, Couplings, Bulkhead Couplings, NPT Plugs, Street Pipe Elbows, Male Pipe Elbows, Male Pipe Tees, Street Pipe Tees and Male Branch Tees.

Pipe Hex Nipples

MAXIMATOR Pipe Hex Nipples are designed for fast system builds. They are available in various lengths for pipe fittings.

In addition to the minimum lengths (Pipe Hex Close Nipples) and various lengths (4" to 8" lengths) available in the MAXIMATOR standard range, Pipe Hex Nipples are also available in custom length. Please consult MAXIMATOR US.

Pipe O-Ring Check Valves

MAXIMATOR Pipe O-Ring Check Valves provide high quality directional flow control and bubble tight shutoff for liquids and gases. These check valves are not to be used as a relief device. The opening pressure of the O-Ring Check Valves is approx. 10 psi (1.5 bar).

Materials

- Body, cover, poppet, cover gland: 316 stainless steel

- Spring: 300 series stainless steel

- O-ring: Viton “A” (-4° F to 392° F)

Pipe Ball Check Valves

MAXIMATOR Pipe Ball Check Valves prevent reverse flow where bubble tight shutoff is not mandatory. These check valves are designed to operate to 660°F. These check valves are not to be used as a relief device. The opening pressure of the Pipe Ball Check Valves is approx. 10 psi (1.5 bar).

Materials

- Body, cover, poppet, cover gland: 316 stainless steel

- Ball: 316 stainless steel

- Spring: 300 series stainless steel

Pipe Line Filters

MAXIMATOR Pipe Line Filters are used to filter process fluids in high pressure systems. The cup type design is used when maximum filtration surface area and a single micron size element is preferred. This design increases the filter area as much as 6 times the area of the disc type filter, and will permit higher flow rates with a lower pressure drop, and longer intervals between element changes. Filter elements come standard in 5, 30, or 56 micron sizes and are easily replaced. Filters are rated for temperatures -60˚ F to 660˚ F (-50° C to 350° C).

Materials

- Body, cover, cover gland: 316 series stainless steel

- Element: 300 series stainless steel