Find your product now in our new webshop!

You can now access detailed product information and data sheets in our new eStore.

Test Stand Features:

• For vessels up to 600L with test pressure up to 12,600 psi

• Cycle times of 5-30min. (depending on vessel volume)

• Fully automatic with transport system for vessel

• Accumulation or vacuum test chambers

• Nitrogen-Helium-Mix or Nitrogen-Hydrogen-Mix test gases

• Includes flushing and OTV functional test

Our leak test stands serve as the functional test for the production of hydrogen composite pressure vessels.

National and international regulations as well as customer specifications mandate end-of-line leak testing to ensure performance and safety of every vessel. The leak test is performed with a tracer gas which allows fast and accurate integral testing in a vacuum or accumulation chamber. During testing, the vessels can be safely pressurized and the tracer gas is recovered during depressurization.

The Hydrogen Leak Test Stand is available in 3 sizes to fit all commonly produced vessel sizes.

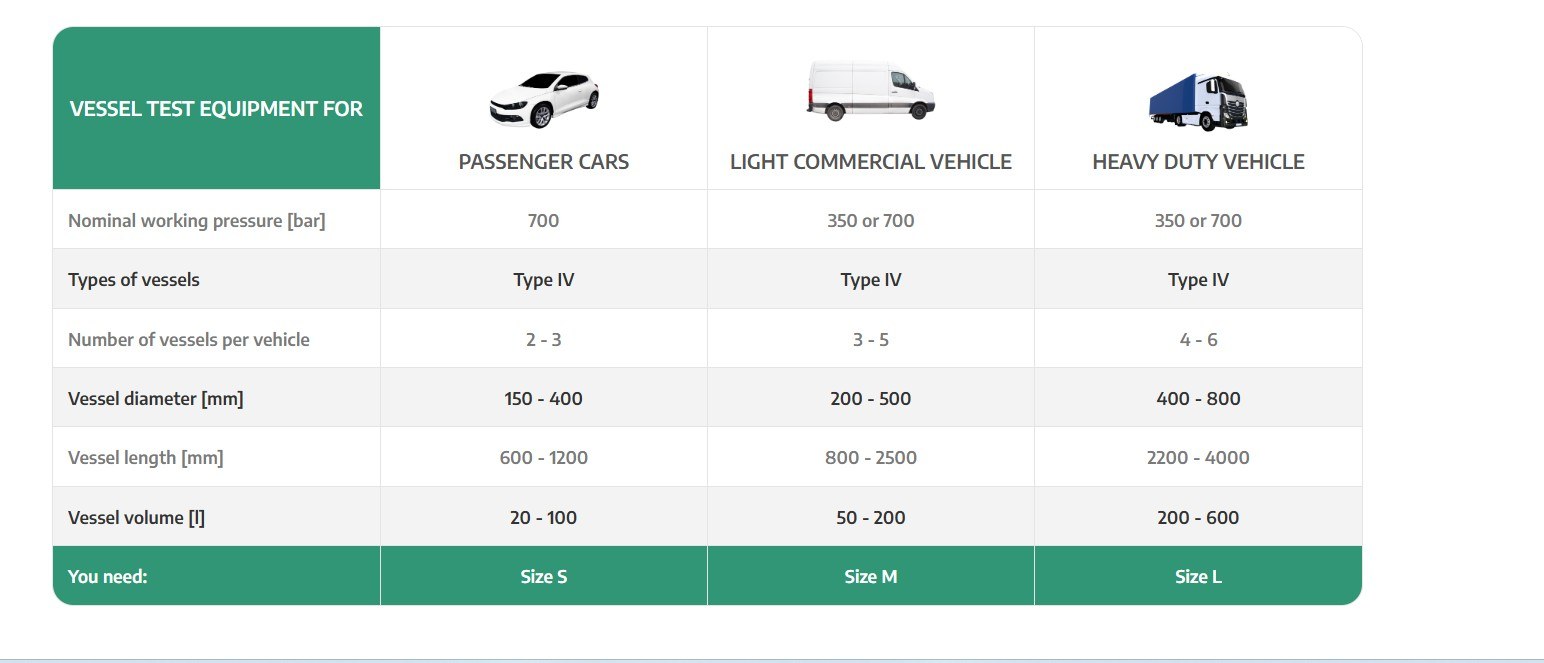

Based on the vessel dimensions and later application, customers can configure the proven modular design in the sizes S, M or L. The chart below shows the delimitations between these 3 different sizes.

Key Benefits

• Handling style: manual or automatic

• Test gas: 95% N2 mixed with 5% H2 or 90% N2 mixed with 10% He

• Measurement: integral with accumulation or vacuum chamber

• Test sample pressure: 5075 psi or 10,150 psi(350 bar or 700 bar)

• Test sample volume: 20-600 L

• Test sample length: 23”- 157” (600-4000 mm)

• Test sample diameter: 6” – 31” (150-800 mm)

• Gas recovery rate: up to 98%

• Flushing process: included with 100% nitrogen

• Cycle time: 5-180 min