Find your product now in our new webshop!

You can now access detailed product information and data sheets in our new eStore.

Hydrogen Valves

- All valves for hydrogen refueling applications are optimized for long service life

- Suitable for operation in the temperature range -40°C up to +85°C according to ISO 19880-3 and ANSI / SAE HGV 4.7

- Valve sizes from 1/4" up to 1"

- Pressure range up to 15.000 psi (1.050 bar)

- Special cleaning for use in hydrogen systems to avoid contamination

- Leakage test on seat and packing with helium at maximum operating pressure

- Specific selection of metallic materials to avoid hydrogen embrittlement

- Dynamic sealing elements for low leakage and long service life

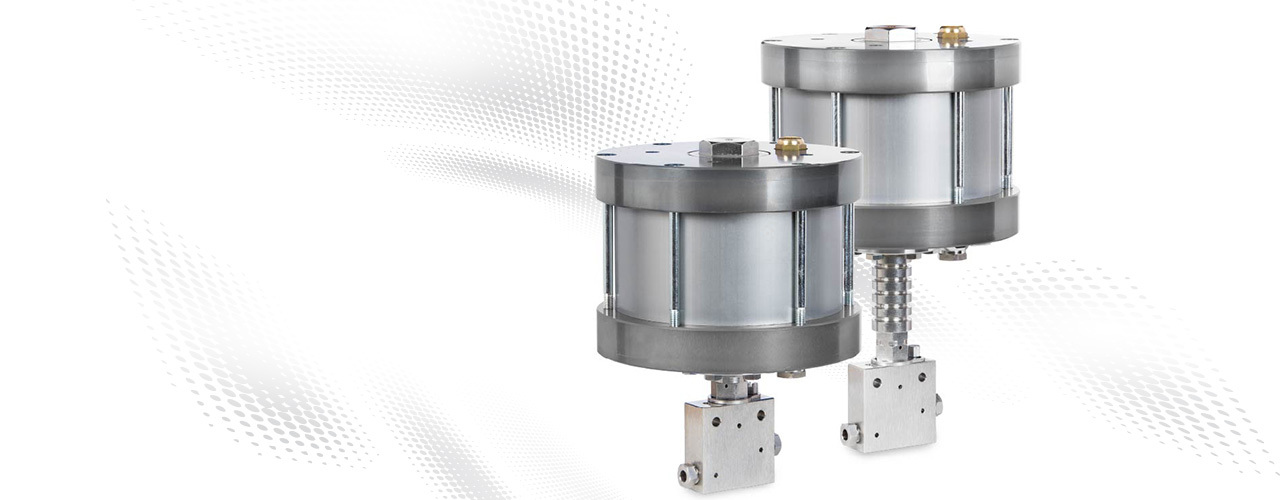

Multi-Functional Dispenser Valve

This valve is to be used on the release side of the filling hose. The multi-porting reduces the need for additional connections, saving space and reducing the risk of leaks.

The stem travel can be adjusted which directly effects the orifice. Hence the vent-down process can be optimized to reduce noise emissions.

The outlet check valve which is located downstream towards the vent line (stack) is integrated as well.

- Reliable normally open needle valve with 3" (75 mm) compressed air drive to be used for pressure release of filling line

- Double porting on left hand side eliminates need for Tee fitting

- Connection for rupture disk

- Check valve integrated on outlet

- Adjustable stem travel = adjustable orifice

- High leak integrity and compact integrated design

- Low wear because of optimal materials of construction

- Weep holes on connections for maximum safety

Hydrogen Cone Check Valve Series 21CC-H2

This check valve is specially designed for hydrogen applications. In contrast to conventional check valves, this valve uses a sealing cone in combination with a soft seal. As a result, the cone check valves impress with excellent sealing properties and a long service life.